SiteScan detects obstructions without costly excavations through our underground utility locator tools.

Before excavating a job site, utility locating services should be utilized to prevent unexpected collisions with existing underground utility lines, pipes, or buried structures. Our line locator equipment allows you to avoid costly and time-consuming issues during trenching, drilling or digging.

It is always a good idea to contact your local utility companies or Call 811 before you dig for preliminary identification of main utility lines before scheduling a comprehensive GPR concrete scan survey.

In addition to public utility location services, we can locate and identify private utilities that may not be serviced by 811.

SiteScan Uses Multiple Technologies to Ensure the Most Accurate Results

We use a combination of methods to positively identify utilities, including Electromagnetic Location and Ground Penetrating Radar (GPR).

We use a combination of methods to positively identify utilities, including Electromagnetic Location and Ground Penetrating Radar (GPR).

Electromagnetic Location combines many advantages and facilities for obtaining information that is not available from any other source. It is often the most common and cost-effective method for locating utilities and the first step in a comprehensive investigation. We use a combination of many different tools to locate utilities electronically including:

Direct Connect – ideal for electrical, communication, and gas lines.

The Direct Connect method involves the technician directly connecting a transmitter to the line. A signal is sent down the utility or tracer wire buried with the utility and located with a receiver from above the surface.

Direct Induction – discharges a radio signal to locate the line.

Induction involves sending a signal through the surface to the utility when you cannot directly connect to it for various reasons. The utility then transmits this signal, which is picked up by a receiver above the surface in the same manner as the Direct Connect method.

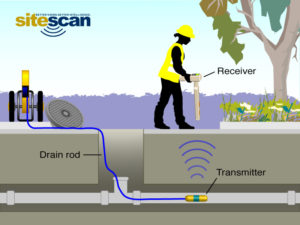

Sonde – gives you the ability to locate non-metallic pipes.

Sonde locating involves inserting a locatable transmitter into a utility or conduit to be discovered by a receiver above the surface. Some of the tools we use that have locatable sondes in them are crawler cameras, push cameras, and ramrods. This method is often used for storm drains, waste lines, and empty conduit.

Ground Penetrating Radar – a non-destructive method that uses radar pulses.

Ground Penetrating Radar works by sending a pulse of energy into a material and recording the strength and the time required for the return of any reflected signal. A series of pulses over a single area make up what is called a scan. Reflections are produced whenever the energy pulse enters into a material with different electrical conduction properties or dielectric permittivity from the material it left. The strength, or amplitude, of the reflection, is determined by the contrast in dielectric constants and conductivities of two materials.

With GPR, our technicians can quickly identify and mark the location and depth of service utilities – gas, communications, and sewer lines – and other metallic and non-metallic targets, including underground storage tanks and PVC pipes.

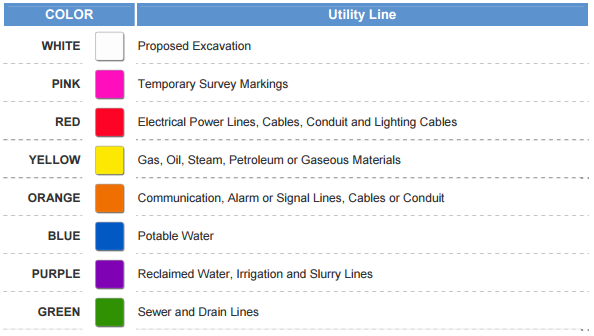

When utilities are located, our technicians use industry-standard colors to mark them directly on the surface. Water-based marking paint is applied when permitted. When paint is not permitted, in cases like finished decorative surfaces or high traffic customer areas, we use chalk, wax, or other marking materials. Flags and whiskers are also used in areas such as grass or dirt when paint markings will not last.

For more information on how GPR and EM work, visit our Resources Page.

Electromagnetic Location of Utilities.

Electromagnetic Location is used not just to find a utility but to identify the type of utility (e.g., cable, power, water, sewer). Because of this, Electromagnetic locating is the most common and cost-effective method for locating utilities and utility lines.

The Electromagnetic Locating method is based on measurements of changes in mutual impedance between a pair of coils on or above the earth’s surface. Most EM instruments consist of two or more sets of coils, which are electrically connected and separated by a fixed distance. The transmitter coil generates an electromagnetic field at a specific frequency, called the primary field. The primary field causes electrical currents to flow in conductive materials in the subsurface. The flow of currents in the subsurface called eddy currents generate a secondary magnetic field, which is sensed by the receiver coil. The magnitude of the secondary field sensed by the receiver depends upon the type and distribution of conductive material in the subsurface. Both the induced secondary field, along with the primary field, is detected at the receiver coil.

The magnitude of the secondary field is broken into two orthogonal components. These are the In-phase (real component) and the Quadrature component (imaginary part). Under certain operating conditions, the magnitude of the Quadrature component of the secondary field is linearly proportional to the apparent conductivity. In the absence of a highly conductive material (e.g., metal or metallic targets) in the subsurface, the magnitude of the in-phase component is dependent on the magnetic susceptibility of the underground.

Our Electromagnetic Location Equipment

We use the most advanced EM equipment available to ensure you get the best results possible. The system structure, electronics, and coils are designed for maximum structural and thermal stability. These key features minimize signal drift and maintain an accurate zero level and system null across the full bandwidth of the system. In comparison, signal drift is a common problem with other EM instruments. Older instruments produce data with significant challenges that cause inaccurate results. You won’t have that issue with SiteScan. We deliver accurate data every time.

We use the most advanced EM equipment available to ensure you get the best results possible. The system structure, electronics, and coils are designed for maximum structural and thermal stability. These key features minimize signal drift and maintain an accurate zero level and system null across the full bandwidth of the system. In comparison, signal drift is a common problem with other EM instruments. Older instruments produce data with significant challenges that cause inaccurate results. You won’t have that issue with SiteScan. We deliver accurate data every time.